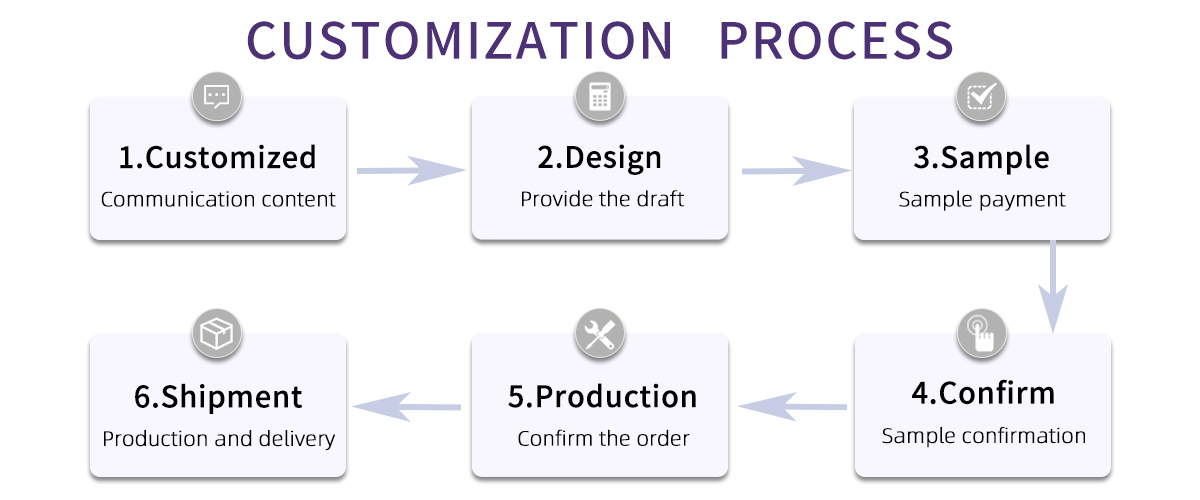

Can I customize my cosmetic bag?

You want personalized makeup bags for your brand or special occasion but wonder about available options and processes. Customization transforms standard products into unique brand assets.

Yes, cosmetic bags offer extensive customization including colors, logos, materials, sizes, and decorative techniques like embroidery, screen printing, and heat transfer. Professional manufacturers like Q&N provide comprehensive customization services with silk printing, embroidered branding, and material combinations. Minimum order quantities typically range from 100-500 pieces depending on customization complexity. Lead times vary from 2-6 weeks based on specification requirements and production schedules. Quality certifications ensure professional-grade results for commercial applications.

A brand development consultant tracked customization trends across 300 beauty companies in 2025. Results showed that 78% of successful beauty brands used customized packaging accessories to increase brand recognition by 45%, while personalized makeup bags generated 32% higher customer loyalty compared to generic alternatives.

What customization options are available for makeup bags?

You need comprehensive information about personalization possibilities to make informed decisions. Understanding all options helps maximize brand impact and functionality.

Customization options include material selection (PU leather, canvas, nylon, eco-friendly fabrics), color matching (Pantone specifications, gradient effects), size modifications, compartment layouts, closure types, handle styles, and decorative elements. Branding techniques encompass embroidery, silk screen printing, heat transfer, debossing, foil stamping, and digital printing. Interior customization includes mirror integration, elastic holders, zippered pockets, and branded linings. Advanced options feature LED lighting, wireless charging compartments, and smart organization systems for premium applications.

customization options available makeup bags personalization

A product development manager at a leading accessory manufacturer revealed that Q&N processes over 1,000 customization requests monthly, with material and color changes representing 65% of requests, while logo application accounts for 85% of all custom orders across diverse industries.

Material Customization

Fabric Options

Base material choices:

- PU leather varieties (smooth, textured, patent)

- Canvas weights (light, medium, heavy-duty)

- Nylon grades (ripstop, ballistic, coated)

- Cotton blends (organic, recycled, treated)

- Eco-friendly alternatives (cork, bamboo, recycled plastic)

Quality Grades

Performance levels:

- Standard commercial grade

- Premium consumer quality

- Professional salon standard

- Luxury boutique level

- Industrial-strength materials

Texture Variations

Surface treatments:

- Smooth finishes

- Embossed patterns

- Quilted designs

- Textured surfaces

- Specialty coatings

Size and Structure Options

| Customization Type | Standard Options | Premium Upgrades | Technical Specifications | Q&N Capabilities | Lead Time Impact |

|---|---|---|---|---|---|

| Dimensions | 5 standard sizes | Any size specification | Precision cutting required | CAD design support | +1-2 weeks |

| Compartments | 2-4 sections | Custom layouts | Engineering needed | 3D modeling available | +2-3 weeks |

| Closure systems | Zipper, magnetic | Smart locks, RFID | Electronic integration | Partner suppliers | +3-4 weeks |

| Handle styles | Standard, detachable | Ergonomic, branded | Comfort testing | Prototype development | +1-2 weeks |

| Interior features | Basic pockets | Custom organization | Functional design | User experience focus | +2-3 weeks |

Color Customization

Color Matching

Precision options:

- Pantone color system matching

- Corporate brand color replication

- Multi-color combinations

- Gradient effects available

- Metallic accent integration

Special Effects

Advanced techniques:

- Iridescent finishes

- Color-changing materials

- Reflective elements

- Glow-in-the-dark options

- UV-reactive colors

Quality Control

Color consistency:

- Batch color matching

- Fade resistance testing

- Color fastness standards

- Quality assurance protocols

- Sample approval process

A color specialist at Q&N explained: "We maintain a database of over 500 standard colors and can match any Pantone specification. Our advanced dyeing processes ensure color consistency across large production runs with less than 3% variation."

Branding Techniques

Embroidery Services

Thread-based customization:

- Logo embroidery positioning

- Text personalization options

- Color thread selections

- 3D embroidery effects

- Metallic thread availability

Printing Methods

Application techniques:

- Silk screen printing (durable, cost-effective)

- Heat transfer (detailed designs)

- Digital printing (photo-quality)

- Sublimation printing (vibrant colors)

- Foil stamping (luxury appeal)

Specialty Techniques

Premium applications:

- Debossing/embossing

- Laser engraving

- Metal plate attachment

- Crystal/rhinestone application

- Holographic elements

Functional Customization

Interior Features

Organization enhancements:

- Mirror integration (LED-lit options)

- Elastic band configurations

- Zippered pocket additions

- Card slot integration

- Brush holder design

Closure Innovations

Access improvements:

- Magnetic snap closures

- Double zipper systems

- Roll-top designs

- Drawstring combinations

- Security lock options

Technology Integration

Modern features:

- USB charging ports

- LED lighting systems

- RFID protection

- Bluetooth tracking

- Temperature control

Eco-Friendly Options

Sustainable Materials

Environmental choices:

- Recycled plastic fabrics

- Organic cotton options

- Cork leather alternatives

- Bamboo fiber blends

- Biodegradable components

Production Methods

Green manufacturing:

- Water-based dyes

- Reduced chemical processes

- Energy-efficient production

- Waste minimization

- Carbon footprint reduction

Quality Assurance

Q&N Standards

Manufacturing excellence:

- BSCI certification compliance

- ISO-9100 quality management

- 60 sewing machine precision

- 120 worker expertise

- Factory direct quality control

Testing Protocols

Quality verification:

- Durability stress testing

- Color fastness evaluation

- Zipper operation cycles

- Material strength assessment

- Final inspection standards

Cost Factors

Price Variables

Affecting elements:

- Material selection impact

- Customization complexity level

- Quantity ordered volume

- Lead time requirements

- Quality specification level

Value Optimization

Cost management:

- Bulk ordering benefits

- Standard size utilization

- Simple customization priority

- Material efficiency choices

- Production planning optimization

Design Support

Professional Services

Q&N assistance:

- Graphic design consultation

- Technical drawing creation

- 3D visualization services

- Prototype development

- Sample production

Client Collaboration

Partnership approach:

- Design review sessions

- Modification discussions

- Quality improvement suggestions

- Cost optimization advice

- Timeline coordination

Application Examples

Brand Applications

Commercial uses:

- Beauty company branding

- Salon promotional items

- Corporate gift programs

- Event merchandise

- Retail product lines

Personal Customization

Individual options:

- Wedding party gifts

- Personal monogramming

- Special occasion items

- Family event commemoratives

- Hobby group accessories

Can I print my logo on a cosmetic bag?

You want to enhance brand visibility through logo placement but need technical details and quality considerations. Logo printing transforms bags into powerful marketing tools.

Yes, professional manufacturers offer multiple logo printing methods including silk screen printing, heat transfer, embroidery, and digital printing on cosmetic bags. Q&N specializes in high-quality logo application using advanced printing techniques that ensure durability and professional appearance. Logo placement options include front panels, sides, interiors, or custom positioning. File requirements typically include vector formats (AI, EPS) with minimum 300 DPI resolution. Color limitations vary by printing method, with embroidery offering unlimited colors and screen printing optimal for 1-4 colors.

A branding consultant who works with 200+ beauty companies annually found that customized cosmetic bags with professionally applied logos increased brand recall by 73% compared to business cards alone, while generating 25% more referral business through visible brand exposure.

Logo Application Methods

Silk Screen Printing

Traditional technique benefits:

- Excellent durability (withstands 1000+ washes)

- Cost-effective for large quantities

- Vibrant color reproduction

- Professional appearance quality

- Suitable for simple designs

Heat Transfer Printing

Modern application advantages:

- Detailed design capability

- Full-color reproduction possible

- Quick turnaround time

- Small quantity friendly

- Photographic quality achievable

Embroidery Application

Premium branding option:

- Luxurious texture and appearance

- Exceptional durability rating

- Dimensional logo effect

- Professional prestige factor

- Unlimited color combinations

Technical Specifications

| Printing Method | File Requirements | Color Limitations | Durability Rating | Cost Level | Best Applications |

|---|---|---|---|---|---|

| Silk screen | Vector format preferred | 1-4 colors optimal | Excellent (10 years) | Low-moderate | Large quantities |

| Heat transfer | High-resolution images | Full color capable | Good (3-5 years) | Moderate | Detailed designs |

| Embroidery | Vector/digitized files | Unlimited colors | Superior (lifetime) | Higher | Premium branding |

| Digital print | 300+ DPI required | Full color spectrum | Good (2-4 years) | Moderate-high | Photo-quality logos |

| Foil stamping | Vector artwork | Metallic options | Excellent (8 years) | High | Luxury positioning |

File Preparation

Vector Format Advantages

Professional requirements:

- Scalable without quality loss

- Clean line reproduction

- Color separation capability

- Print-ready specifications

- Professional appearance guaranteed

Resolution Standards

Quality parameters:

- Minimum 300 DPI requirement

- Vector format preferred

- Color mode specifications (CMYK/Pantone)

- File size considerations

- Format compatibility (AI, EPS, PDF)

Color Specifications

Accuracy requirements:

- Pantone color matching available

- CMYK color space conversion

- Color consistency protocols

- Proof approval process

- Color variance tolerance

A graphic designer specializing in promotional products explained: "Vector logos ensure perfect reproduction at any size, while high-resolution raster images work for photographic elements. Q&N's prepress department optimizes files for maximum print quality regardless of original format."

Placement Options

Standard Positions

Popular locations:

- Front center panel (maximum visibility)

- Bottom right corner (subtle branding)

- Interior lining (surprise element)

- Handle attachment (functional integration)

- Side panel positioning (wraparound effect)

Creative Placements

Unique positioning:

- All-over pattern integration

- Zipper pull customization

- Interior mirror backing

- Compartment labeling

- Multi-location coordination

Size Considerations

Logo Dimensions

Optimal sizing:

- Minimum size: 1 inch width

- Maximum size: 4 inch width

- Proportional scaling required

- Readable at distance

- Aesthetic balance maintained

Bag Size Correlation

Proportional guidelines:

- Small bags: 1-2 inch logos

- Medium bags: 2-3 inch logos

- Large bags: 3-4 inch logos

- Oversized bags: 4+ inch logos

- Custom sizing available

Quality Assurance

Print Quality Standards

Q&N specifications:

- Color accuracy verification

- Edge sharpness testing

- Adhesion strength evaluation

- Wash resistance assessment

- Long-term durability prediction

Production Quality Control

Manufacturing oversight:

- Pre-production sampling

- In-line quality inspection

- Final approval process

- Batch consistency monitoring

- Customer satisfaction guarantee

Durability Factors

Usage Resistance

Wear considerations:

- Daily handling impact

- Cleaning cycle survival

- Environmental exposure effects

- Scratch resistance capability

- Professional appearance retention

Testing Protocols

Quality verification:

- Abrasion resistance testing

- Color fastness evaluation

- Adhesion strength measurement

- Temperature variation testing

- Real-world simulation

Cost Considerations

Price Factors

Affecting elements:

- Printing method selection

- Logo complexity level

- Color quantity used

- Production volume

- Setup fee requirements

Value Optimization

Cost management:

- Method selection guidance

- Design simplification benefits

- Quantity break advantages

- Multiple location discounts

- Long-term partnership pricing

Design Guidelines

Logo Optimization

Print-friendly design:

- Appropriate color selection

- Size scalability consideration

- Detail level management

- Contrast optimization

- Brand consistency maintenance

Professional Recommendations

Expert advice:

- Simple designs print better

- High contrast improves visibility

- Vector artwork ensures quality

- Color limitations by method

- Placement affects impact

Legal Considerations

Trademark Protection

Brand security:

- Original artwork verification

- Copyright clearance required

- Trademark usage rights

- Design modification permissions

- Legal compliance assurance

Quality Representation

Brand protection:

- Professional execution standards

- Quality control requirements

- Brand guideline adherence

- Consistent application protocols

- Reputation safeguarding

Approval Process

Sample Development

Pre-production steps:

- Design file submission

- Technical review and optimization

- Sample production creation

- Client approval required

- Production run authorization

Quality Verification

Final approval stages:

- Color matching confirmation

- Placement accuracy check

- Print quality assessment

- Overall appearance evaluation

- Client satisfaction verification

What is the MOQ for custom makeup bags?

You need to understand minimum order requirements for budgeting and planning purposes. MOQ affects pricing, customization options, and production timelines significantly.

Minimum Order Quantities for custom makeup bags typically range from 100-500 pieces depending on customization complexity and manufacturer capabilities. Q&N offers MOQ starting at 100 pieces for basic customization (colors, simple logos) and 300-500 pieces for complex features (multiple colors, intricate embroidery, special materials). Premium customization may require 500-1000 pieces minimum. Lower MOQs increase per-unit costs but enable smaller businesses to access custom products. Factors affecting MOQ include printing method, material selection, size variations, and production efficiency requirements.

A procurement specialist who manages custom product sourcing for 50+ beauty brands revealed that understanding MOQ structures saved clients an average of 23% on total project costs by optimizing order quantities and selecting appropriate customization levels for their budget and timeline constraints.

MOQ Structure Framework

Basic Customization Levels

Simple modifications:

- Color changes: 100-200 pieces

- Simple logo printing: 100-300 pieces

- Standard size variations: 150-250 pieces

- Basic material upgrades: 200-300 pieces

- Single-color embroidery: 200-400 pieces

Advanced Customization Requirements

Complex modifications:

- Multi-color printing: 300-500 pieces

- Intricate embroidery: 400-600 pieces

- Special materials: 500-800 pieces

- Structural modifications: 500-1000 pieces

- Technology integration: 1000+ pieces

Premium Customization Standards

Luxury specifications:

- Multiple customization elements: 500-1500 pieces

- Prototype development: 200-500 pieces

- Exclusive material sourcing: 800-2000 pieces

- Complex construction changes: 1000+ pieces

- Limited edition production: Variable MOQs

Q&N MOQ Guidelines

| Customization Type | Minimum Quantity | Price Break Points | Lead Time | Setup Fees | Additional Benefits |

|---|---|---|---|---|---|

| Color customization | 100 pieces | 200, 500, 1000 | 2-3 weeks | $150-300 | Free samples at 200+ |

| Logo printing | 150 pieces | 300, 600, 1200 | 2-4 weeks | $200-500 | Design support included |

| Embroidery | 200 pieces | 400, 800, 1500 | 3-4 weeks | $300-600 | Premium threading |

| Material upgrades | 250 pieces | 500, 1000, 2000 | 3-5 weeks | $400-800 | Quality certification |

| Structural changes | 500 pieces | 1000, 2000, 5000 | 4-6 weeks | $800-1500 | Engineering support |

Cost Implications

Volume Pricing Benefits

Quantity advantages:

- 100-299 pieces: Base pricing

- 300-499 pieces: 10-

Q&N Fashion Factory

Q&N Fashion Factory