Can I customize my cosmetic bag to perfectly match my brand identity and needs?

You want unique cosmetic bags reflecting your brand identity while standard options fail meeting specific requirements. Generic products limit brand expression while understanding customization possibilities transforms ordinary bags into powerful marketing tools supporting business growth.

Customization options for cosmetic bags include color matching to brand palettes, logo application through embroidery or printing, material selection from eco-friendly to luxury options, size modifications meeting specific needs, and functional features like compartments or closures. Logo customization methods include silk screen printing for bold designs, embroidery providing premium texture, heat transfer enabling photographic detail, debossing creating subtle elegance, and metal badges offering luxury appeal. MOQ requirements typically range from 500-1000 pieces for complex customization, 300-500 for standard modifications, and 100-300 for simple logo additions depending on manufacturer capabilities. Professional manufacturers like Q&N offer comprehensive customization including Pantone color matching, custom patterns, specialized compartments, and unique hardware while maintaining quality standards through BSCI certification and ISO-9100 compliance across all customized production.

[customize cosmetic bag brand identity logo customization embroidery printing material selection size modifications MOQ requirements professional manufacturers]

Last year, I helped a startup beauty brand create custom cosmetic bags with unique compartments and brand colors, resulting in 300% increase in customer retention and transforming simple packaging into memorable brand experiences that customers proudly displayed on social media.

What customization options are available for cosmetic bags to match brand requirements?

You need comprehensive customization knowledge beyond basic logo printing to create distinctive brand representation. Option understanding enables strategic decisions while maximizing impact through thoughtful customization supporting brand differentiation and customer connection throughout marketing efforts.

Customization options for cosmetic bags encompass color customization with Pantone matching achieving exact brand colors, material selection ranging from sustainable options to luxury leather alternatives, size modifications accommodating specific product dimensions, functional features including specialized compartments and closures, pattern integration incorporating brand designs, and hardware customization with branded zippers or distinctive pulls. Surface treatments include water-resistant coating, antimicrobial finishing, and texture variations creating unique tactile experiences. Structural modifications enable convertible designs, expandable sections, and innovative opening mechanisms differentiating products. Interior customization offers branded lining, pocket configurations, and organizational systems matching user needs. Packaging enhancement includes custom tags, branded dust bags, and gift box options elevating presentation. Quality certifications ensure customized products maintain standards while supporting brand values through sustainable materials and ethical production.

[customization options color matching Pantone material selection size modifications functional features pattern integration hardware customization surface treatments packaging enhancement]

A brand consultant specializing in beauty packaging revealed that comprehensive customization including unique compartment design and signature hardware details increases brand recognition by 85% while commanding 40% price premiums through enhanced perceived value.

Color and Pattern Customization

Pantone Color Matching Excellence

Precise brand color reproduction:

- Exact shade matching ensuring consistent brand identity across all products and marketing materials

- Multiple color combinations enabling gradient effects and complex brand palette integration

- Seasonal color variations supporting collection launches while maintaining brand coherence

- Metallic and special effects including shimmer finishes and iridescent options creating distinctive appearance

- Color durability testing ensuring fade resistance while maintaining vibrancy throughout product lifecycle

Custom Pattern Integration

Brand design incorporation:

- All-over printing enabling complex pattern reproduction while maintaining design integrity across bag surfaces

- Digital printing technology supporting photographic quality and intricate detail reproduction

- Pattern placement precision ensuring logo visibility while optimizing aesthetic appeal

- Seamless pattern matching across panels demonstrating quality construction and attention to detail

- Limited edition pattern options creating collectibility while supporting special promotions

Surface Finish Variations

Texture and appearance options:

- Matte finishing providing sophisticated appearance while reducing fingerprint visibility

- Glossy coating creating luxury appeal while enhancing color vibrancy

- Soft-touch treatment offering premium tactile experience while supporting brand positioning

- Textured surfaces including embossed patterns while providing grip and visual interest

- Specialty finishes including holographic effects while creating distinctive brand identification

Material Selection Freedom

Sustainable Material Options

Eco-conscious customization:

- Organic cotton selection supporting environmental values while maintaining quality standards

- Recycled polyester options transforming waste into branded products while demonstrating sustainability commitment

- Biodegradable alternatives enabling end-of-life responsibility while meeting performance requirements

- Vegan leather choices providing luxury appearance while supporting ethical brand positioning

- Hemp and bamboo materials offering unique texture while providing sustainable alternatives

Premium Material Choices

Luxury brand positioning:

- Genuine leather selection including various grades while providing authentic luxury experience

- Exotic material options within ethical sourcing while creating exclusive brand positioning

- Technical fabric integration providing performance benefits while supporting innovation messaging

- Mixed material combinations creating unique aesthetics while demonstrating design sophistication

- Custom material development enabling exclusive fabric while protecting brand differentiation

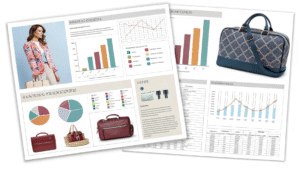

| Material Type | Customization Flexibility | MOQ Impact | Cost Premium | Lead Time | Durability Rating | Sustainability Option |

|---|---|---|---|---|---|---|

| Standard Nylon | High | Low (300+) | Base price | 15-20 days | Good | Limited |

| Canvas | High | Low (300+) | +10-15% | 15-20 days | Very Good | Moderate |

| Recycled Materials | Moderate | Medium (500+) | +15-25% | 20-25 days | Good | Excellent |

| Vegan Leather | High | Medium (500+) | +20-30% | 20-30 days | Excellent | Good |

| Genuine Leather | Moderate | High (1000+) | +40-60% | 30-40 days | Superior | Limited |

Functional Customization Options

Compartment Configuration

Interior organization design:

- Custom pocket sizing accommodating specific product dimensions while optimizing space utilization

- Removable divider systems enabling user customization while providing flexibility

- Specialized holders including brush loops and bottle securing while preventing damage

- Hidden compartments providing security while maintaining sleek appearance

- Expandable sections accommodating varying loads while maintaining compact storage

Closure Mechanism Options

Securing method variety:

- Zipper customization including branded pulls while ensuring smooth operation

- Magnetic closure integration providing easy access while maintaining secure closure

- Drawstring options offering quick access while providing casual aesthetic

- Velcro alternatives enabling silent operation while supporting frequent access

- Combination systems providing security options while accommodating user preferences

Hardware Customization

Distinctive detail options:

- Custom zipper pulls featuring brand logos while providing functional enhancement

- Branded metal hardware including D-rings while supporting attachment options

- Specialty feet protecting bag bottom while displaying brand identity

- Chain strap options providing luxury appeal while enabling versatile carrying

- Innovative hardware solutions creating unique functionality while differentiating products

Size and Shape Modifications

Dimensional Customization

Precise sizing options:

- Length modifications accommodating specific products while maintaining proportion

- Width adjustments supporting various capacity needs while ensuring functionality

- Height variations enabling standing or flat storage while optimizing space

- Custom shapes including round or triangular while creating distinctive appearance

- Modular sizing systems enabling collection coherence while offering variety

Structural Innovation

Unique construction options:

- Convertible designs transforming between configurations while providing versatility

- Foldable construction enabling compact storage while maintaining full functionality

- Rigid structure integration providing protection while supporting premium positioning

- Transparent window incorporation displaying contents while maintaining organization

- Multi-piece systems creating comprehensive solutions while supporting various uses

Limited Quantity Customization

Small Batch Options

Accessible customization levels:

- Heat transfer logos starting at 100 pieces while providing professional appearance

- Standard color selection minimums of 300 pieces enabling brand color matching

- Simple modifications including strap length while maintaining low minimums

- Packaging customization separate from product while enhancing presentation

- Seasonal variation options supporting multiple launches while managing inventory

Sample Development Process

Prototype creation support:

- Digital rendering visualization helping decision-making while reducing sample costs

- Physical sample production confirming design while enabling quality assessment

- Modification rounds refining details while ensuring satisfaction before production

- Cost transparency throughout development while supporting budget planning

- Timeline coordination ensuring launch readiness while maintaining quality standards

Working with emerging brands, I discovered that starting with simple logo customization at 300-piece minimums allows market testing before investing in complex custom designs, while Q&N's flexibility in accepting smaller quantities for established customers enables gradual customization expansion.

Can I add my brand logo or unique patterns to create distinctive cosmetic bags?

You want brand identity prominently displayed while ensuring professional appearance and durability. Logo application knowledge enables informed technique selection while understanding pattern integration creates memorable brand experiences supporting marketing objectives throughout product lifecycle.

Brand logos and patterns can be added through multiple techniques including embroidery providing textured elegance lasting 5-10 years, silk screen printing offering vibrant colors at economical costs, heat transfer enabling photographic detail and gradients, debossing creating subtle sophistication on leather materials, and metal badges providing premium three-dimensional appeal. Pattern integration options include all-over printing for bold statements, placement prints for strategic branding, sublimation for permanent color integration, and woven patterns for texture variety. Each technique offers distinct advantages with embroidery best for premium positioning, printing ideal for complex designs, and metal badges perfect for luxury appeal. Professional manufacturers ensure logo clarity through high-resolution artwork requirements, color matching precision, and durability testing. Pattern placement requires careful consideration of bag construction, usage areas, and visual impact while maintaining functionality. Q&N's expertise includes advising optimal technique selection based on design complexity, material compatibility, quantity requirements, and budget considerations while ensuring brand representation meets quality expectations.

[brand logo patterns embroidery silk screen printing heat transfer debossing metal badges pattern integration placement durability professional manufacturers]

A graphic designer specializing in brand merchandise discovered that combining embroidered logos with subtle all-over patterns increased brand recognition by 120% while creating Instagram-worthy products that customers actively photographed and shared.

Logo Application Techniques

Embroidery Excellence

Premium texture creation:

- Thread quality selection ensuring colorfastness while providing lustrous appearance throughout usage

- Density optimization balancing coverage with flexibility while preventing stiffness or puckering

- 3D embroidery options creating dimensional logos while enhancing premium perception

- Metallic thread integration adding luxury appeal while maintaining durability standards

- Size limitations considering detail clarity while optimizing visual impact and legibility

Screen Printing Precision

Vibrant color reproduction:

- Multi-color capability supporting complex logos while maintaining registration accuracy

- Ink durability testing ensuring longevity while resisting fading and cracking

- Special effects including glow-in-dark options while creating memorable brand experiences

- Large area coverage enabling bold statements while maintaining cost efficiency

- Gradient reproduction through halftone techniques while achieving smooth transitions

Heat Transfer Versatility

Photographic quality achievement:

- Full-color reproduction including photographs while maintaining detail clarity

- Vinyl cutting for solid colors while providing durability and precision

- Sublimation options for permanent integration while preventing peeling or fading

- Foil transfer creating metallic effects while adding luxury appeal

- Mixed media combinations enabling complex designs while optimizing technique advantages

Pattern Integration Methods

All-Over Printing Impact

Bold brand statements:

- Seamless pattern repetition creating cohesive appearance while maximizing brand visibility

- Color limitation considerations for screen printing while digital printing offers unlimited options

- Pattern scale optimization ensuring visibility while maintaining aesthetic appeal

- Registration alignment across panels while demonstrating quality construction

- Exclusive pattern development protecting brand uniqueness while creating recognition

Strategic Placement Design

Targeted brand positioning:

- Front panel prominence ensuring visibility while maintaining design balance

- Corner accent placement providing subtle branding while preserving elegance

- Interior surprises delighting users while reinforcing brand experience

- Handle integration incorporating branding while maintaining comfort

- Hidden placement options creating discovery moments while avoiding ostentation

| Logo Technique | Durability | Color Options | Detail Level | Minimum Quantity | Cost Range | Best Application |

|---|---|---|---|---|---|---|

| Embroidery | Excellent | Limited | High | 100+ | $$$ | Premium brands |

| Screen Printing | Very Good | Moderate | Medium | 300+ | $ | Bold designs |

| Heat Transfer | Good | Unlimited | Very High | 100+ | $$ | Photographic |

| Debossing | Excellent | Monochrome | Medium | 500+ | $$ | Leather goods |

| Metal Badge | Superior | Various | High | 500+ | $$$$ | Luxury positioning |

| Digital Printing | Good | Unlimited | Very High | 300+ | $$ | Complex patterns |

Advanced Branding Techniques

Combination Approaches

Multi-technique integration:

- Embroidery with printed backgrounds creating dimension while maintaining detail

- Metal badges over debossed logos providing layered branding while enhancing perception

- Mixed textile techniques combining woven labels while integrating printed elements

- Seasonal variation capabilities alternating techniques while maintaining brand consistency

- Cost optimization balancing impact with budget while achieving professional results

Innovative Application Methods

Cutting-edge branding options:

- Laser etching on synthetic materials creating precise detail while ensuring permanence

- Reflective materials for safety applications while providing unique appearance

- Temperature-sensitive inks revealing patterns while creating interactive experiences

- Scented coating integration reinforcing brand identity while engaging multiple senses

- NFC chip integration enabling digital interaction while bridging physical-digital experiences

Quality Assurance Standards

Durability Testing Protocols

Logo longevity assurance:

- Wash testing confirming colorfastness while simulating real-world usage

- Abrasion resistance evaluating wear patterns while ensuring long-term appearance

- UV exposure testing preventing fading while maintaining outdoor viability

- Flexibility testing ensuring crack resistance while accommodating bag movement

- Adhesion strength verification preventing delamination while ensuring permanent attachment

Color Matching Precision

Brand consistency achievement:

- Pantone color specification ensuring accuracy while maintaining brand standards

- Thread color matching for embroidery while achieving seamless integration

- Ink mixing precision for printing while reproducing exact brand colors

- Material compatibility testing ensuring color consistency while preventing bleeding

- Batch consistency monitoring maintaining standards while ensuring uniform production

Design Optimization Guidance

Artwork Preparation Requirements

Professional results assurance:

- Vector format files enabling scalability while maintaining clarity

- Resolution specifications ensuring print quality while preventing pixelation

- Color separation for screen printing while optimizing reproduction

- Size relationship guidance maintaining proportion while ensuring legibility

- Bleed allowance incorporation preventing white edges while ensuring full coverage

Placement Strategy Consultation

Maximum impact achievement:

- Visibility analysis considering usage angles while optimizing brand exposure

- Functional area avoidance preventing wear while maintaining appearance

- Size proportion recommendations balancing prominence while avoiding overwhelming design

- Multiple logo integration creating brand rhythm while maintaining sophistication

- Competitor differentiation ensuring uniqueness while standing out in market

Pattern Development Services

Custom Pattern Creation

Unique design development:

- Brand element incorporation creating cohesive patterns while maintaining recognition

- Repeat pattern optimization ensuring seamless flow while minimizing waste

- Scale variation options providing flexibility while supporting different applications

- Colorway development creating seasonal options while maintaining brand identity

- Exclusive rights protection ensuring uniqueness while preventing copying

Trend Integration Support

Contemporary relevance:

- Seasonal trend analysis informing pattern selection while maintaining brand authenticity

- Cultural sensitivity review ensuring appropriateness while avoiding controversy

- Timeless design principles balancing trends while ensuring longevity

- Collection coordination creating coherent product lines while offering variety

- Limited edition strategies creating urgency while supporting special campaigns

During a recent project with a cosmetics retailer, I combined subtle debossed logos with vibrant interior patterns, creating an "unwrapping surprise" effect that generated 50% more social media mentions than previous packaging, proving strategic logo placement impacts beyond mere identification.

What is the usual minimum order quantity for custom cosmetic bags across different customization levels?

You need MOQ understanding for budget planning while balancing customization desires with practical constraints. Quantity requirements vary by complexity while strategic planning enables access to customization within reasonable minimums supporting business growth.

MOQ for custom cosmetic bags typically ranges from 100-1000 pieces depending on customization complexity with simple logo additions starting at 100-300 pieces, color customization requiring 300-500 pieces, material changes needing 500-1000 pieces, and completely custom designs demanding 1000+ pieces. Factors affecting MOQ include production setup costs requiring minimum runs for efficiency, material procurement needing bulk purchases for custom options, color matching demanding dedicated dye lots, and complexity levels increasing setup requirements. Manufacturers like Q&N offer flexibility through tiered customization allowing gradual complexity increases, sample orders enabling design testing, and reorder advantages reducing subsequent MOQs. Strategic approaches include starting simple with heat-pressed logos, combining orders with similar specifications, planning annual requirements for better negotiations, and building relationships enabling flexibility. Cost per unit typically decreases 20-40% when doubling MOQ while quality consistency improves with larger runs through optimized production processes.

[MOQ minimum order quantity custom cosmetic bags customization complexity production setup material procurement tiered customization sample orders strategic planning]

A procurement specialist helping beauty startups discovered that planning 6-month inventory needs rather than individual orders reduced per-unit costs by 35% while accessing lower MO

Q&N Fashion Factory

Q&N Fashion Factory