What companies produce plastic bags?

Finding reliable plastic bag manufacturers creates confusion among buyers seeking quality and consistency. Poor supplier selection leads to defective products and damaged business relationships.

Major plastic bag companies include Novolex, Berry Global, and Chinese manufacturers like Q&N. These companies produce various plastic bags from grocery bags to specialized cosmetic storage using PU and PVC materials trending in 2025.

After 15 years manufacturing bags at Q&N in Guangzhou, I've observed the plastic bag industry evolve dramatically. Our company represents the new generation of Chinese manufacturers combining traditional plastic processing with innovative cosmetic bag design.

What is a cosmetic bag?

Many people underestimate the specialized engineering behind quality cosmetic bags. These products require careful material selection and design optimization for beauty product storage needs.

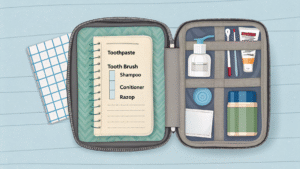

A cosmetic bag is a specialized storage container designed with compartments and materials optimized for organizing makeup, skincare, and beauty tools. Modern designs use PU and PVC materials for durability and easy cleaning.

Cosmetic bags serve multiple functions beyond simple storage containers. Protection of fragile makeup items requires padding and cushioning materials. Organization systems help users locate products quickly during busy morning routines. Portability features enable travel without damaging expensive beauty investments.

Design considerations address specific beauty product challenges. Liquid foundations need leak-proof storage preventing damage to other items. Powder compacts require cushioning against breaking during drops or impacts. Brushes need shape protection while allowing air circulation for hygiene maintenance.

Material selection directly impacts bag performance and user satisfaction. PU materials trending in 2025 offer excellent durability with leather-like appearance at affordable costs. PVC provides superior water resistance for humid bathroom environments. Both materials clean easily with damp cloths after makeup spills.

Our Q&N factory specializes in cosmetic bags using advanced PU and PVC materials. These synthetic materials offer advantages over traditional fabric options through consistent quality, color retention, and maintenance simplicity. Manufacturing processes allow precise control over texture, flexibility, and appearance characteristics.

Size categories accommodate different beauty routines and storage needs. Mini bags hold essential touch-up items for purses or travel. Small bags suit basic daily makeup collections. Medium bags accommodate complete beauty routines. Large bags serve professional makeup artists or extensive product collections.

Quality construction techniques ensure long-term durability under regular use. Reinforced stress points prevent tearing at zipper attachments and handle connections. Premium zippers operate smoothly after thousands of uses. Double-stitched seams withstand weight from heavy glass bottles or large compacts.

The 2025 trend toward PU and PVC cosmetic bags reflects consumer preferences for easy maintenance and consistent appearance. Unlike fabric bags that show stains and wear patterns, synthetic materials maintain original appearance longer. This durability justifies initial investment through extended useful life.

Modern cosmetic bags incorporate smart organizational features addressing contemporary beauty routines. Adjustable dividers accommodate changing product collections. Clear compartments allow quick product identification. Elastic loops secure cylindrical items preventing rolling and damage.

| Bag Feature | PU Material Benefits | PVC Material Benefits |

|---|---|---|

| Appearance | Leather-like texture | Glossy or matte finish |

| Durability | Excellent flexibility | Superior water resistance |

| Maintenance | Easy wipe cleaning | Simple soap and water |

| Cost | Moderate pricing | Budget-friendly option |

| Environmental | Better recyclability | Chemical resistance |

What is the best makeup bag brand?

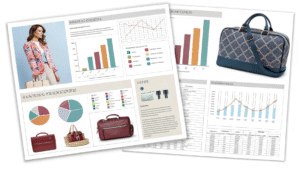

Brand selection significantly impacts product quality, durability, and customer satisfaction. I evaluate makeup bag brands based on materials, construction, and real-world performance.

The best makeup bag brands combine quality materials, thoughtful design, and reliable manufacturing. Q&N leads innovation with PU and PVC materials trending in 2025 while offering customizable solutions for international markets.

Brand evaluation requires understanding manufacturing capabilities behind marketing claims. Many popular brands outsource production to Chinese manufacturers while focusing on design and marketing. Q&N represents direct manufacturing excellence without middleman markups affecting final pricing.

Quality indicators separate excellent brands from mediocre options. Material consistency across production runs demonstrates manufacturing control. Hardware reliability indicates attention to component selection. Construction durability reveals long-term performance capabilities under regular use conditions.

Our Q&N brand builds reputation through manufacturing excellence rather than marketing budgets. BSCI and ISO-9100 certifications ensure ethical labor practices and quality management systems. Direct relationships with international clients eliminate distribution markups while maintaining quality standards.

Innovation drives brand differentiation in competitive cosmetic bag markets. Our 2025 focus on PU and PVC materials addresses consumer demands for easy maintenance and durability. Advanced manufacturing techniques create sophisticated textures and finishes previously available only in expensive leather products.

Customization capabilities distinguish manufacturing brands from retail brands. Q&N offers logo customization, color matching, and compartment modifications for business clients. This flexibility serves beauty brands, promotional companies, and retailers requiring specific design elements.

Price positioning reflects brand strategy and target market focus. Luxury brands charge premium prices for heritage and exclusivity. Value brands sacrifice quality for low pricing. Q&N balances quality materials and construction with competitive pricing through efficient manufacturing.

Customer satisfaction metrics provide objective brand performance measurements. Return rates indicate real-world durability and functionality. Repeat purchase patterns show customer loyalty and satisfaction. Our Q&N products achieve consistently low return rates across international markets.

Global market reach demonstrates brand capabilities and reliability. Established brands serve multiple countries with consistent quality standards. Q&N exports to North America, Europe, Australia, and Japan while maintaining quality consistency across all markets.

The shift toward PU and PVC materials in 2025 positions Q&N advantageously against traditional brands slow to adopt new materials. Our manufacturing expertise with synthetic materials creates superior products at competitive prices compared to brands outsourcing production.

Environmental considerations increasingly influence brand selection among conscious consumers. PU materials offer better recyclability than traditional leather options. Manufacturing processes minimize waste and environmental impact. Sustainable practices attract environmentally aware customers seeking responsible brands.

What is the best material for a cosmetic bag?

Material selection determines cosmetic bag performance, appearance, and longevity more than any other factor. I help customers understand material properties and their practical implications.

The best cosmetic bag materials for 2025 include PU and PVC synthetics offering durability, water resistance, and easy maintenance. These materials surpass traditional fabrics through consistent quality and sophisticated appearance options.

PU materials dominate 2025 cosmetic bag trends through superior performance characteristics and aesthetic appeal. Polyurethane offers leather-like texture and appearance without animal-derived materials. Manufacturing processes create various surface textures from smooth to grain patterns matching traditional leather appearances.

Durability advantages make PU materials ideal for daily cosmetic bag use. Excellent tear resistance prevents damage from sharp objects like tweezers or nail files. Flexibility prevents cracking under repeated folding and handling. Color retention maintains original appearance despite exposure to makeup products and cleaning.

Water resistance properties protect bag contents from bathroom moisture and accidental spills. Foundation leaks remain contained without penetrating material surfaces. Humidity exposure during travel or storage doesn't damage PU materials. Easy cleaning with damp cloths removes makeup residue and stains.

PVC materials offer different advantages for specific cosmetic bag applications. Superior chemical resistance handles exposure to nail polish removers, perfumes, and other cosmetic solvents. Glossy surfaces create modern aesthetic appeal while providing excellent stain resistance. Lower costs make PVC attractive for budget-conscious consumers.

Manufacturing flexibility allows precise control over PU and PVC material properties. Thickness variations accommodate different strength requirements and weight considerations. Texture options range from smooth surfaces to embossed patterns. Color consistency exceeds natural material variations.

Our Q&N factory specializes in advanced PU and PVC processing techniques. Heat bonding creates seamless constructions without visible stitching lines. Embossing equipment produces sophisticated textures and patterns. Quality control ensures consistent material properties across all production runs.

Environmental considerations favor synthetic materials over traditional leather options. PU materials require less water and chemical processing than leather tanning. Recyclability options exist for end-of-life disposal. Manufacturing processes generate less environmental waste than animal hide processing.

Cost effectiveness makes PU and PVC materials attractive for various market segments. Premium appearance at moderate costs appeals to value-conscious consumers. Consistent pricing avoids natural material market fluctuations. Manufacturing efficiency reduces production costs compared to traditional materials.

Performance comparisons demonstrate synthetic material advantages over fabric alternatives. PU and PVC resist staining better than canvas or nylon. Water resistance prevents damage to bag contents. Easy maintenance saves time and effort compared to fabric cleaning requirements.

The 2025 trend toward synthetic cosmetic bag materials reflects changing consumer preferences and manufacturing capabilities. Modern PU and PVC materials offer sophisticated appearances previously limited to expensive natural materials. Q&N leads this trend through innovative material development and manufacturing excellence.

| Material Property | PU Performance | PVC Performance | Traditional Fabric |

|---|---|---|---|

| Water Resistance | Excellent | Superior | Poor to Moderate |

| Durability | Very Good | Good | Variable |

| Appearance Options | Extensive | Moderate | Limited |

| Maintenance | Easy | Very Easy | Difficult |

| Cost | Moderate | Low | Variable |

| Environmental Impact | Moderate | Moderate | Variable |

Conclusion

Plastic bag companies like Q&N lead cosmetic bag innovation with PU and PVC materials trending in 2025, offering superior durability and maintenance advantages.

Q&N Fashion Factory

Q&N Fashion Factory