What is the best fabric for bag making?

Selecting optimal fabric for bag making requires understanding material properties, intended use, durability requirements, and aesthetic goals affecting long-term performance and consumer satisfaction. Poor fabric choices result in premature failure, inadequate functionality, and disappointing user experience affecting brand reputation and customer loyalty.

Cotton canvas and nylon emerge as top bag-making fabrics through durability and versatility, while matte nylon and waterproof canvas make strong comeback this year combining practicality with premium aesthetics for sophisticated bag construction requiring both function and style.

Through our Q&N manufacturing experience producing bags for global markets over 15 years, I've observed how fabric selection determines both functionality and market positioning across different consumer segments. The resurgence of matte nylon and waterproof canvas reflects growing consumer demand for materials that deliver practical performance while maintaining sophisticated aesthetic appeal essential for premium positioning.

What material is used for cosmetic packaging?

Cosmetic packaging materials must meet safety standards, product compatibility, and aesthetic requirements while providing adequate protection and user experience. Inappropriate material selection leads to product contamination, packaging failure, and regulatory compliance issues affecting brand reputation and consumer safety.

Glass, plastic polymers, and aluminum dominate cosmetic packaging through safety compliance and product protection, while secondary packaging increasingly features matte nylon and waterproof canvas materials combining durability with premium positioning for carrying cases and gift sets.

Glass packaging provides premium positioning through transparency, chemical inertness, and recyclability making it ideal for high-end skincare and fragrance applications requiring product integrity protection. Chemical inertness prevents product contamination and ingredient degradation ensuring product efficacy and safety. Transparency enables product visibility supporting consumer confidence and aesthetic appeal. Recyclability aligns with environmental sustainability goals and consumer expectations.

Barrier properties of glass prevent oxygen and moisture penetration protecting sensitive formulations from degradation and contamination. UV protection variants shield light-sensitive ingredients from degradation during storage and display. Temperature stability maintains packaging integrity across storage and shipping conditions. Tamper resistance supports product safety and consumer confidence.

Our Q&N manufacturing expertise extends to cosmetic packaging accessories where matte nylon and waterproof canvas materials provide sophisticated solutions for carrying cases, gift sets, and retail presentation enhancing overall brand experience and perceived value.

Plastic polymers offer versatility, cost efficiency, and design flexibility enabling diverse packaging solutions across cosmetic categories and price points. Polyethylene provides chemical resistance and flexibility for squeeze bottles and flexible packaging. Polypropylene offers clarity and heat resistance for caps and rigid containers. Polystyrene delivers clarity and moldability for compact cases and dispensers.

Advanced plastic formulations incorporate specialized properties addressing specific cosmetic packaging requirements and consumer preferences. UV-resistant formulations protect light-sensitive products during retail display and consumer use. Antimicrobial additives prevent bacterial growth in packaging reducing contamination risks. Recycled content options support sustainability goals without compromising performance.

Aluminum packaging combines barrier properties with premium aesthetics and recyclability making it suitable for various cosmetic applications requiring protection and prestige positioning. Excellent barrier properties prevent moisture and oxygen penetration protecting product integrity. Lightweight construction reduces shipping costs and environmental impact. Malleability enables complex shapes and decorative treatments enhancing aesthetic appeal.

Laminated materials combine multiple substrates optimizing barrier properties, printability, and functionality for flexible packaging applications requiring specific performance characteristics. Foil laminations provide excellent barrier properties for sensitive formulations. Paper laminations enable high-quality graphics and tactile appeal. Plastic laminations optimize puncture resistance and sealability.

Sustainable packaging materials address environmental concerns through renewable resources, biodegradability, and recyclability appealing to environmentally conscious consumers and regulatory requirements. Biodegradable plastics break down naturally reducing environmental impact. Renewable resource materials utilize plant-based feedstocks. Refillable containers reduce packaging waste through repeated use.

Secondary packaging materials including bags, boxes, and carrying cases increasingly utilize premium materials like matte nylon and waterproof canvas providing functional elegance for retail presentation and consumer use. Gift packaging creates premium unboxing experience enhancing brand perception. Carrying cases extend product utility and brand engagement beyond initial purchase. Retail display packaging attracts consumer attention and communicates brand values.

Child-resistant packaging meets regulatory requirements for products potentially harmful to children through specialized closures and barrier systems. Push-and-turn closures require specific manipulation preventing child access. Blister packaging provides individual dose protection with access difficulty. Specialized caps incorporate safety mechanisms meeting regulatory standards.

| Packaging Material | Barrier Properties | Safety Level | Cost Efficiency | Aesthetic Appeal | Sustainability |

|---|---|---|---|---|---|

| Glass | Excellent | Very High | Medium | Premium | Very High |

| Plastic Polymers | Variable | High | High | Versatile | Improving |

| Aluminum | Excellent | High | Medium | Premium | High |

| Laminated Materials | Excellent | High | Medium | Good | Variable |

| Sustainable Options | Variable | High | Variable | Good | Excellent |

| Secondary Materials | Variable | Medium | Variable | Premium | Variable |

What is the best material to make a bag out of?

Optimal bag materials depend on intended use, durability requirements, aesthetic preferences, and budget considerations requiring careful evaluation of material properties and performance characteristics. Incorrect material selection results in premature failure, inadequate functionality, and consumer dissatisfaction affecting brand reputation and market success.

Canvas and nylon represent optimal bag materials through exceptional durability and versatility, with matte nylon and waterproof canvas experiencing strong comeback this year combining practical performance with premium aesthetics for sophisticated bag construction across various applications.

Canvas materials provide exceptional durability through tight weave construction and natural fiber strength making them ideal for heavy-duty applications requiring long-term reliability and abuse resistance. Heavy-duty canvas weights from 12-24 ounces provide maximum durability for work bags and outdoor applications. Medium-weight canvas offers good durability with improved flexibility for everyday bags. Lightweight canvas provides adequate strength with enhanced portability for casual applications.

Natural canvas properties include breathability, moldability, and aging characteristics creating distinctive appearance over time. Cotton canvas accepts dyes excellently enabling vibrant colors and custom printing. Hemp canvas provides enhanced durability with environmental sustainability benefits. Linen canvas offers lightweight strength with premium tactile qualities.

Our Q&N manufacturing operations demonstrate how canvas selection affects both performance and aesthetic appeal with waterproof canvas treatments enhancing functionality while maintaining natural fiber appeal essential for premium positioning in competitive markets.

Nylon dominates technical bag applications through superior strength-to-weight ratio, abrasion resistance, and weather protection making it essential for travel and outdoor use requiring maximum performance. Ripstop nylon prevents tear propagation through reinforcing grid construction. Cordura nylon provides exceptional abrasion resistance for high-wear applications. Ballistic nylon offers maximum durability for professional and tactical uses.

Performance characteristics of nylon include water resistance, quick drying, and color retention ensuring reliable performance across diverse conditions and extended use. Chemical treatments enhance water repellency preventing moisture penetration. UV resistance maintains color integrity under sun exposure. Easy cleaning enables simple maintenance and hygiene preservation.

Matte nylon finishes provide sophisticated aesthetics eliminating shiny appearance while maintaining technical performance characteristics appealing to fashion-conscious consumers seeking functional elegance. Reduced glare improves visual appeal in professional settings. Subtle texture enhances tactile experience and perceived quality. Premium positioning supports higher margins and brand differentiation.

Leather materials offer luxury positioning through natural beauty, aging character, and traditional craftsmanship though requiring higher investment and specialized care. Full-grain leather provides maximum durability with distinctive patina development over time. Top-grain leather offers consistent appearance with good durability for most applications. Exotic leathers provide unique aesthetics with premium positioning potential.

Leather processing affects durability, appearance, and maintenance requirements influencing suitability for different bag types and consumer preferences. Chrome tanning produces soft, flexible leather with consistent properties. Vegetable tanning creates natural aging characteristics with environmental appeal. Oil tanning provides weather resistance with enhanced durability.

Synthetic materials provide cost-effective alternatives with enhanced performance characteristics and ethical positioning appealing to diverse consumer segments and applications. Synthetic leather offers leather aesthetics with improved water resistance and easier maintenance. Technical synthetics incorporate advanced properties like antimicrobial treatments and stain resistance. Recycled synthetics address environmental concerns while maintaining performance.

Polyester fabrics provide versatile option with good durability, color retention, and easy care properties suitable for various bag applications and price points. Microfiber polyester offers premium feel with enhanced performance characteristics. Recycled polyester addresses sustainability concerns without compromising functionality. Textured polyester provides visual interest and improved tactile experience.

Specialty fabrics address specific performance requirements through advanced technology and innovative constructions meeting demanding applications and consumer expectations. Waterproof breathable fabrics combine moisture protection with comfort. Antimicrobial fabrics prevent bacterial growth and odor development. Reflective fabrics enhance safety and visibility for outdoor applications.

Material combinations optimize performance through strategic construction blending complementary properties for enhanced functionality and aesthetic appeal. Canvas exterior with waterproof lining combines durability with moisture protection. Leather accents on synthetic bases provide luxury touches with practical benefits. Multiple material zones optimize performance for specific bag areas and functions.

Construction techniques affect material performance requiring appropriate methods for different fabric types and applications ensuring optimal durability and appearance. Reinforced seaming prevents failure at stress points during regular use. Proper interfacing provides structure and shape retention. Quality hardware selection complements material choices for cohesive performance and aesthetics.

| Material Type | Durability | Water Resistance | Maintenance | Aesthetics | Cost Level |

|---|---|---|---|---|---|

| Heavy Canvas | Exceptional | Good (treated) | Moderate | Traditional/Rugged | Medium |

| Technical Nylon | Very High | Excellent | Very Easy | Modern/Technical | Medium-High |

| Matte Nylon | Very High | Excellent | Very Easy | Sophisticated/Premium | High |

| Quality Leather | Very High | Variable | High | Luxury/Classic | High |

| Synthetic Leather | Medium-High | Good | Easy | Leather-like | Medium |

| Performance Polyester | High | Good | Easy | Versatile | Low-Medium |

What materials are makeup bags made of?

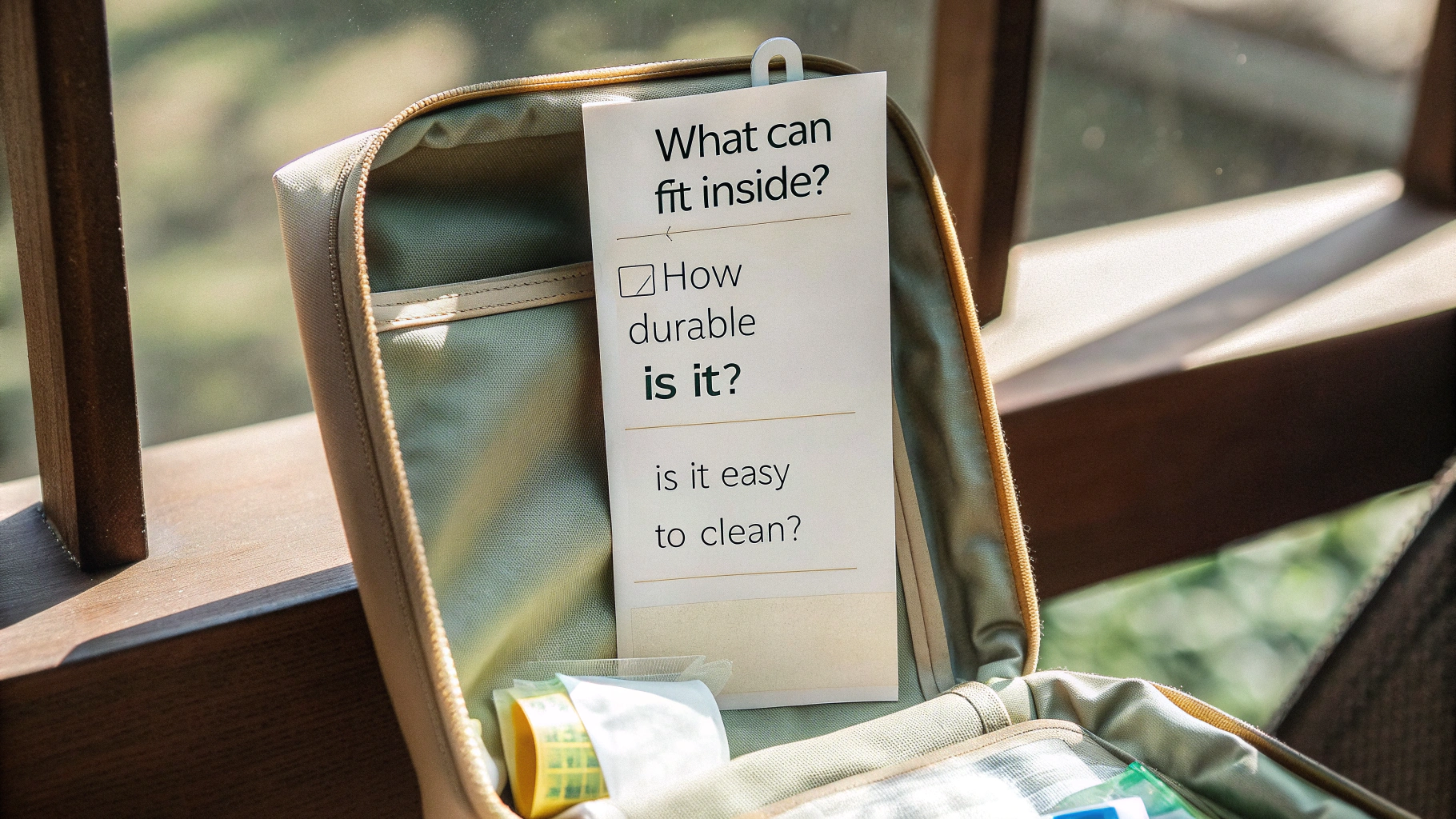

Makeup bag materials must provide protection for cosmetic products, easy cleaning for hygiene maintenance, and aesthetic appeal for daily use requiring careful selection based on functionality and user preferences. Poor material choices result in staining, difficult cleaning, and inadequate protection affecting user experience and product longevity.

Nylon and polyester dominate makeup bag construction through water resistance and easy cleaning properties, while matte nylon and waterproof canvas materials experience strong comeback combining practical performance with premium aesthetics for sophisticated cosmetic storage solutions.

Nylon leads makeup bag material selection through exceptional water resistance, lightweight properties, and easy maintenance making it ideal for travel and daily use applications. Water resistance prevents liquid spills from penetrating fabric protecting bag contents and exterior surfaces. Lightweight construction reduces travel weight while maintaining structural integrity through repeated use. Easy cleaning enables simple maintenance through wiping or gentle washing procedures.

Ripstop nylon varieties provide enhanced tear resistance through specialized weaving preventing small punctures from expanding into larger tears. High-denier nylon constructions offer maximum durability for frequent use and harsh treatment. Packable nylon enables space-saving storage when not in use. Antimicrobial treatments prevent bacterial growth and odor development in frequent-use applications.

Our Q&N manufacturing specializes in cosmetic bag production where material selection determines both functionality and market positioning with matte nylon and waterproof canvas materials providing sophisticated solutions combining practical performance with premium aesthetic appeal essential for brand differentiation.

Polyester provides cost-effective alternative maintaining beneficial properties including stain resistance, color retention, and durability making it suitable for budget-conscious consumers without sacrificing basic functionality. Stain resistance prevents permanent discoloration from cosmetic spills and accidents. Quick-drying properties facilitate easy cleaning and rapid return to service. Color retention maintains aesthetic appeal through repeated washing and use.

Microfiber polyester varieties offer enhanced softness and premium tactile experience while maintaining practical benefits of standard polyester construction. Recycled polyester options appeal to environmentally conscious consumers without compromising performance characteristics. Water-resistant treatments enhance functionality for cosmetic storage applications.

Canvas materials offer natural fiber appeal with excellent durability and customization potential though requiring treatments for optimal cosmetic bag performance. Cotton canvas provides breathable properties and accepts custom printing excellently. Waxed canvas treatments add water resistance while maintaining natural fiber aesthetics. Heavy-duty canvas constructions withstand frequent use without structural degradation.

Waterproof canvas combines traditional canvas appeal with enhanced functionality through specialized treatments providing moisture protection while maintaining natural texture and appearance. Breathable waterproof treatments prevent condensation buildup inside bags. Durable water repellent finishes maintain effectiveness through repeated use and cleaning. Natural appearance preservation maintains aesthetic appeal with enhanced functionality.

Vinyl and PVC materials provide maximum water resistance and easy sanitization though with less premium aesthetics requiring careful design integration for market acceptance. Complete waterproof properties protect contents from all moisture exposure. Easy sanitization enables thorough cleaning and hygiene maintenance. Chemical resistance prevents degradation from cosmetic ingredients and cleaning products.

Clear vinyl options enable content visibility for organization and TSA compliance during travel. Textured vinyl finishes reduce fingerprint visibility and improve tactile experience. Flexible vinyl constructions accommodate various product shapes and sizes. Antimicrobial treatments prevent bacterial growth on frequently touched surfaces.

Silicone materials provide innovative option combining flexibility, complete water resistance, and easy cleaning with modern aesthetic

Q&N Fashion Factory

Q&N Fashion Factory