Who produces the most plastic bags?

Identifying the world's largest plastic bag producers helps buyers understand global manufacturing capacity and quality standards. Poor supplier knowledge leads to unreliable partnerships and product quality issues.

China produces the most plastic bags globally, with companies like Novolex and Berry Global leading in North America. Q&N represents specialized cosmetic bag manufacturing focusing on 2025 travel bag trends with advanced materials and portable designs.

After manufacturing bags for 15 years at our Q&N facility in Guangzhou, I've witnessed China's dominance in global plastic bag production. Our region alone houses thousands of bag manufacturing facilities serving international markets with specialized products.

How is a plastic bag manufacturer?

Understanding plastic bag manufacturing processes helps buyers evaluate supplier capabilities and quality standards. I explain our Q&N manufacturing approach to demonstrate modern production excellence.

Plastic bag manufacturers operate through injection molding, blow molding, or film extrusion processes depending on product types. Q&N combines traditional plastic processing with specialized cosmetic bag assembly for travel applications trending in 2025.

Modern plastic bag manufacturing begins with raw material selection and preparation. Polyethylene pellets undergo melting and mixing with colorants or additives. Quality control testing ensures consistent material properties before processing. Our Q&N facility maintains strict incoming material standards for cosmetic bag production.

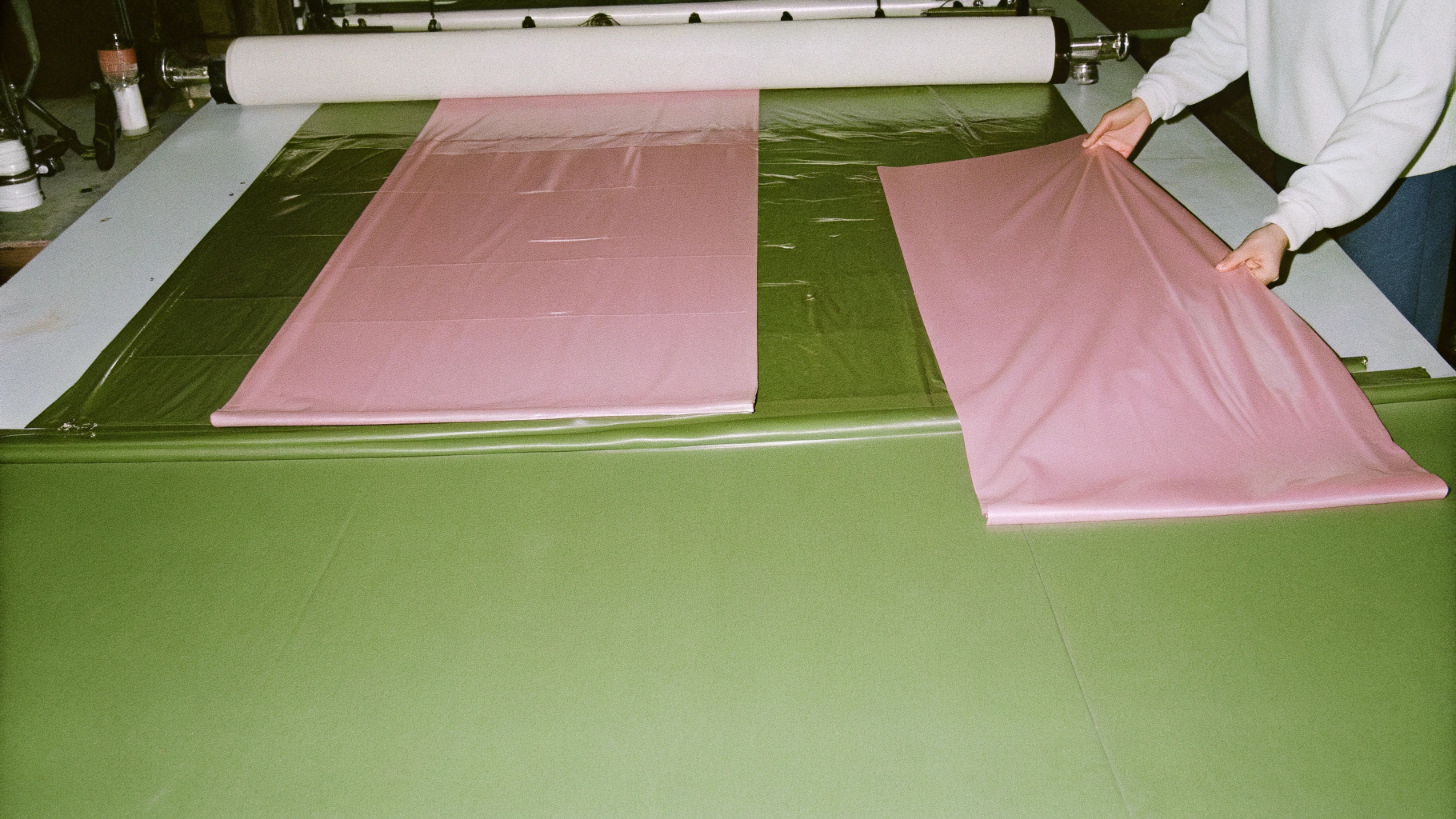

Extrusion processes create plastic films used in flexible bag manufacturing. Heated plastic passes through dies creating continuous film sheets. Thickness control systems maintain consistent material properties. Film winding equipment prepares materials for subsequent processing steps.

Converting operations transform plastic films into finished bags through cutting, sealing, and printing processes. Heat sealing creates watertight seams essential for cosmetic bag applications. Precision cutting ensures accurate dimensions and professional appearance. Quality control checkpoints verify seam strength and dimensional accuracy.

Our Q&N manufacturing approach combines plastic processing with specialized textile techniques. Travel cosmetic bags require zippers, handles, and compartmentalization beyond simple plastic bag construction. Advanced sewing equipment handles both plastic materials and fabric components in integrated production lines.

Quality management systems ensure consistent production across large volume orders. Statistical process control monitors critical parameters throughout manufacturing. Incoming material inspection prevents defective components from entering production. Final product testing validates performance specifications before shipment.

Automation levels vary significantly between manufacturers affecting quality consistency and production efficiency. Modern facilities incorporate automated material handling, cutting, and sealing equipment. Computer-controlled systems reduce human error and improve repeatability. Our Q&N investment in automation ensures consistent quality for international clients.

Environmental considerations drive manufacturing process improvements and material selection. Waste reduction programs minimize material consumption and disposal costs. Energy efficiency measures reduce production costs and environmental impact. Recycling programs handle production waste and end-of-life products.

Capacity planning addresses seasonal demand variations and growth projections. Flexible manufacturing systems adapt to changing product mix requirements. Cross-training programs ensure workforce availability across different production areas. Strategic equipment investments support expansion into new product categories.

The 2025 focus on travel cosmetic bags requires specialized manufacturing capabilities beyond standard plastic bag production. Multi-compartment designs need precision assembly techniques. Premium materials demand careful handling and processing. Quality standards exceed typical plastic bag requirements.

Worker training programs ensure consistent quality and safety standards throughout production operations. Technical skill development supports advanced manufacturing processes. Safety training prevents workplace accidents and maintains productivity. Continuous improvement programs encourage employee suggestions and innovations.

| Manufacturing Aspect | Standard Plastic Bags | Cosmetic Travel Bags | Q&N Advantages |

|---|---|---|---|

| Material Complexity | Simple films | Multi-material construction | Advanced processing capability |

| Assembly Requirements | Heat sealing only | Sewing, hardware, zippers | Integrated production lines |

| Quality Standards | Basic functionality | Premium appearance and durability | ISO-9100 certification |

| Design Flexibility | Limited options | Extensive customization | In-house design team |

What is a cosmetic bag called?

Cosmetic bag terminology varies globally and across different market segments. I clarify naming conventions to help customers communicate requirements effectively with manufacturers.

Cosmetic bags are also called makeup bags, beauty bags, toiletry bags, or vanity cases depending on size and intended use. Travel cosmetic bags trending in 2025 emphasize portability and TSA compliance for modern travelers.

[cosmetic bag terminology types]

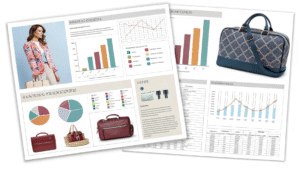

Regional naming preferences reflect cultural differences and market positioning strategies. American consumers typically use "makeup bag" for smaller items and "cosmetic bag" for larger storage solutions. European markets prefer "beauty bag" or "vanity case" terminology. Understanding regional preferences helps manufacturers communicate effectively with international clients.

Size-based naming conventions help customers select appropriate products for their needs. Mini makeup bags hold essential touch-up items for purses or pockets. Travel cosmetic bags accommodate complete beauty routines while meeting airline carry-on restrictions. Large vanity cases serve extensive makeup collections or professional applications.

Functional terminology describes specific bag capabilities and intended applications. Toiletry bags focus on hygiene products rather than makeup items. Brush rolls protect makeup brushes during storage and travel. Organizer bags emphasize compartmentalization for efficient product arrangement.

Our Q&N design team develops travel cosmetic bags specifically for the 2025 market emphasizing portability and functionality. These bags incorporate TSA-compliant sizing, clear compartments for security screening, and lightweight materials for easy transport. Marketing terminology reflects travel-focused benefits and convenience features.

Professional terminology used within the beauty industry provides more specific product descriptions. Makeup artists use "kit bags" for professional tool storage. Beauty brands refer to "branded cosmetic pouches" for promotional items. Retailers categorize products as "travel beauty organizers" for specific market segments.

Material-based naming sometimes describes construction characteristics affecting performance and appearance. Leather cosmetic bags emphasize premium materials and traditional craftsmanship. Plastic toiletry bags highlight water resistance and easy cleaning. Fabric makeup bags focus on style variety and lightweight properties.

The trend toward travel cosmetic bags in 2025 creates new terminology emphasizing mobility and convenience. "Travel beauty essentials bags" target frequent travelers. "Compact makeup organizers" appeal to minimalist beauty routines. "TSA-friendly cosmetic cases" address air travel requirements.

Cultural considerations influence naming preferences and marketing approaches across different countries. Asian markets often prefer cute or diminutive terms for beauty accessories. Western markets emphasize functionality and organization benefits. Middle Eastern markets may focus on privacy and discretion aspects.

Brand-specific terminology creates product differentiation and market positioning advantages. Premium brands use sophisticated terms like "beauty compendium" or "cosmetic collection case." Value brands emphasize practical terms like "makeup storage bag" or "beauty organizer." Our Q&N brand focuses on functional benefits and quality construction.

E-commerce platforms require specific terminology for search optimization and customer discovery. Popular search terms include "makeup bag," "cosmetic pouch," "beauty case," and "travel toiletry bag." Understanding search patterns helps manufacturers optimize product listings and marketing materials.

How is cosmetic packaging made?

Cosmetic packaging manufacturing involves diverse processes and materials depending on product requirements. I explain manufacturing approaches from our Q&N perspective producing travel cosmetic bags.

Cosmetic packaging manufacturing uses injection molding for rigid containers, blow molding for bottles, and specialized assembly for bags and cases. Q&N produces travel cosmetic bags through multi-step processes combining materials, hardware, and precise assembly techniques.

[cosmetic packaging manufacturing process]

Cosmetic packaging encompasses various product categories requiring different manufacturing approaches. Rigid containers use injection molding processes similar to standard plastic manuf

Q&N Fashion Factory

Q&N Fashion Factory